From drawing to final product

Starting from the engineering drawing of the new product, our technical team develops, studies, and realizes the mold for the customer. CAD CAM software to produce prototypes allow speed and flexibility of realization. Our team design process included tryout phase so we can offer best possible solution and manufacturing process optimization for rubber products producers.

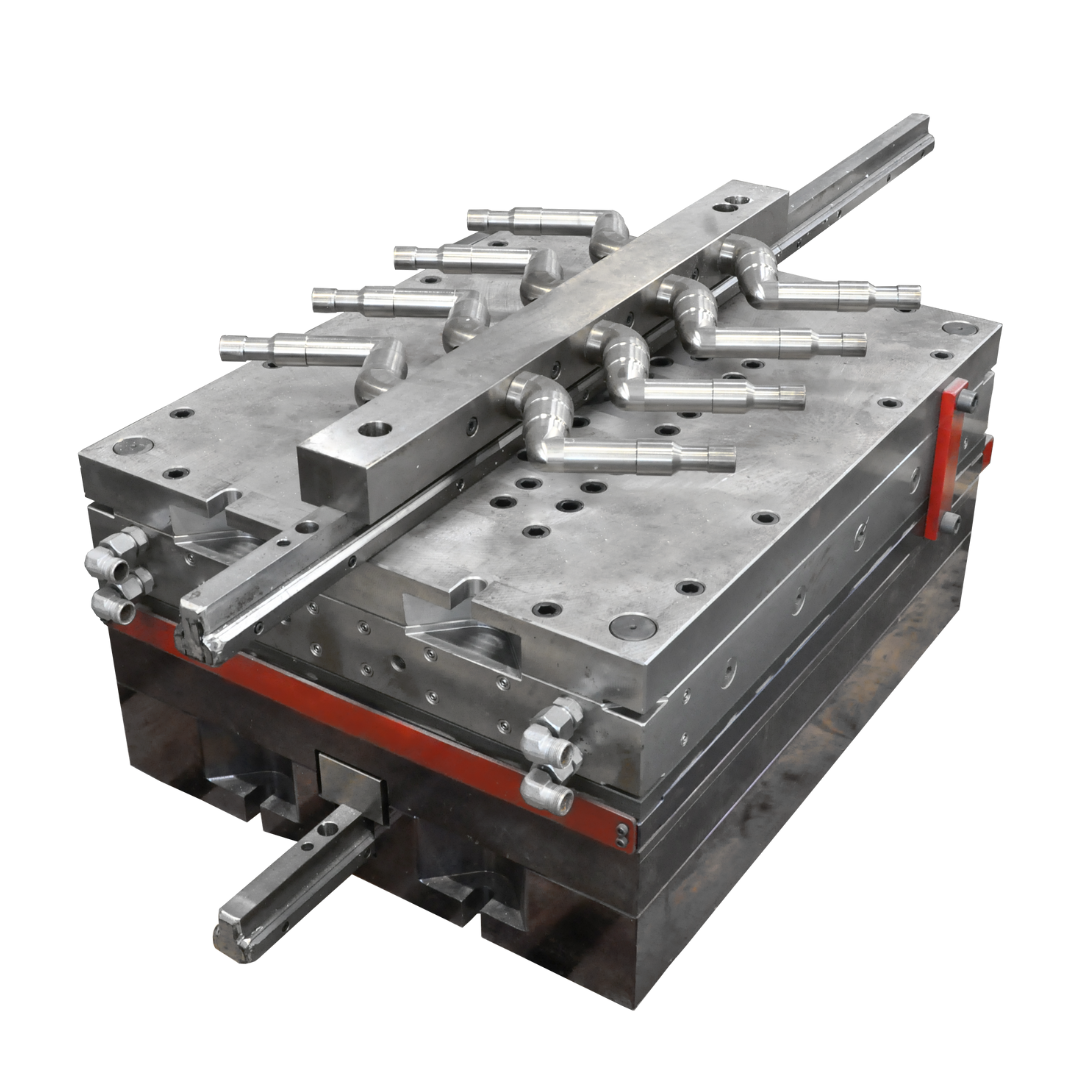

The molds are manufactured using CNC machine tools, milling, grinding and turning machines. G Mold tools for rubber injection moulding are high-precision molds with minimal waste of material.

Molds optimized for modern factories

Functionality of molds is in focus of our construction team. In design of rubber tools our team considers all aspect of manufacturing rubber parts. First step is functionality with rubber injection machine and operators’ efficiency. All aspects that involve the rubber injection moulding of a technical rubber part are taking place in tool desing. We developed systems to improve the moulding cycle time, reduction of waste, tighter tolerances and process automation.

High-quality tools for superior products

Our portfolio of rubber injection molds:

- Made of high-quality mold steels;

- Contain “cold runner” systems supplied by best global producers;

- Enable swift of manufacturing processes;

- Include support from our team in product designing.