Expertise in design and manufacturing

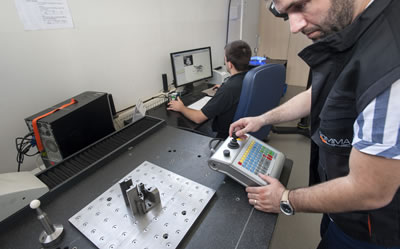

The synergy of modern CAM/CAD sofware, 3D scanning and accumulated knowledge in mold and tool design positioned G Mold as trusted supplier of tools and molds for rubber industry. Research and Development is center place for all projects at G Mold. Our team test solutions that will satisfy the expectations of the customer and offer optimal manufacturing process. Research and direct collaboration regarding decision of material specifications, compatability with rubber injection machines and operator efficiency makes out team ahead in product development and minimizing correction time.

We offer solutions

Our team takes care of the entire production process of the tools, molds, dies starting with consultacy with customers. At this stage, we advise client based on the consolidated know-how on final product requerements so we decide on optimal number of nest based on rubber injection machine dimensions, If there is need for reverse engineering, to makk product based on sample, we conduct a 3D scanning and or check previous technical data and make first CAD models.

Going from the mold design and CAD drawings, we step to next phase of mold design where we discuss rubber products manufacturing and with our client optimize the proces, reduce material waste and discuss process parameters. For the mold production we use our modern tooling equipment including multi-axis CNC machines. All moulds are tested before delivering the final mold to client. G Mold also offers mold maintenance and repairs.